Casting holes

As learning and experimenting should never cease in order to evolve and progress, I'm glad to have done some more pieces that will inform and refine my work process.

For some forms, the clay and concrete seem to have an even more symbiotic relationship than I first realised.

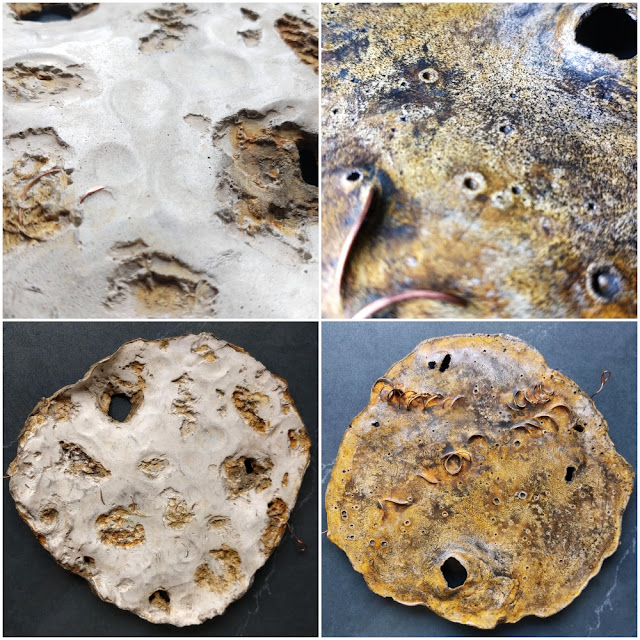

The clay forms shown in the previous post with the negative features of burnt away combustable matter I intend to use for casting. I'd like both capture those features that were only possible to achieve during a kiln firing as well as combine these with the qualities of cast concrete. The clay becomes important again now as I used it to make and imprint (negative form) of the fired piece. I then walled it up with more clay so I could cast the concrete mix into it in order to get a copy of the original that I could modify further.

I used different properties of clay and concrete here: clay dissolves in water, concrete cures or hardens through water. When the concrete had cured, I washed the clay off and got a successful result.

Process of the casting:

|

| The said ceramic sample I made, using copper carbonate and manganese to bring out the burnt out texture |

|

| making a clay imprint, wall it off, cast a white concrete mix into it ... |

|

| ... and washing the clay away when the concrete had set, then stain with the same oxides i used with the clay original |

Comments

Post a Comment